Guardians of Power: The Silent Protectors of Defense Vehicles

In the unforgiving landscapes of the battlefield—where rough terrains, rocky inclines, and unpredictable shocks can cripple even the most advanced defense vehicles—every component must be engineered to endure. Among these unsung heroes, wire rope isolators play a crucial role in safeguarding one of the most vital assets: the vehicle’s battery system.

Captain Arjun surveyed the convoy moving through the mountainous region, their armored personnel carriers crawling over jagged terrain. The mission was critical—transporting electronic warfare units deep into hostile territory. Every piece of equipment relied on uninterrupted power from their advanced lithium-ion battery packs. But the constant vibrations and shocks from the rough terrain posed a significant threat to battery stability.

That’s where the wire rope isolators came into play.

Strategic Placement: The Art of Protection

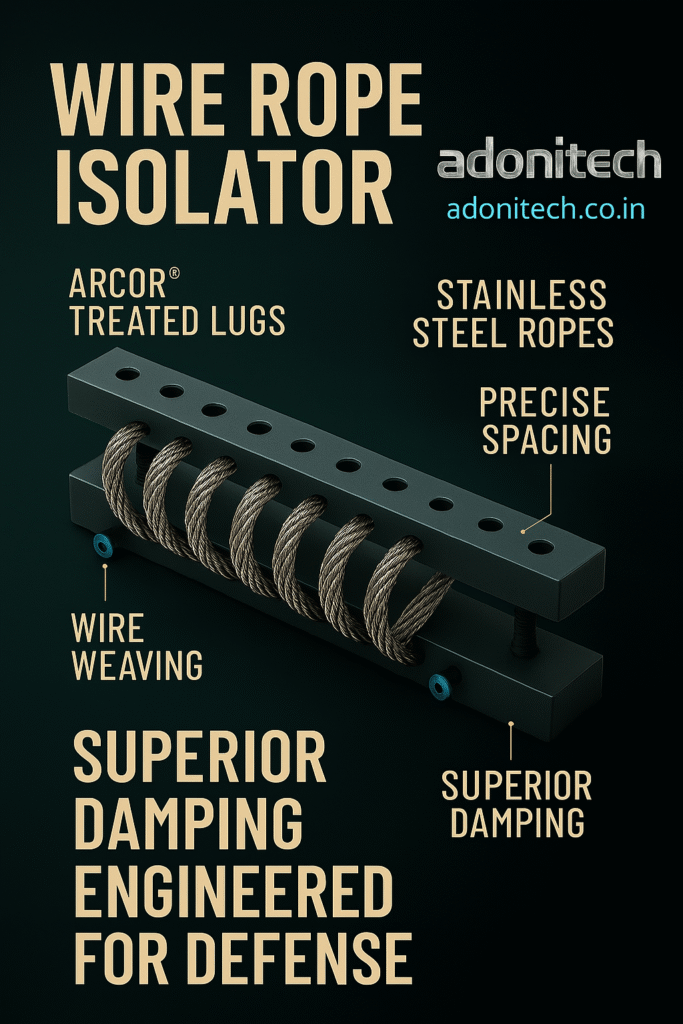

Before deployment, engineers carefully installed wire rope isolators within the battery compartment. These isolators—crafted from intertwined stainless steel cables—were positioned at crucial mounting points surrounding the battery pack. The goal? To absorb and dissipate vibrational energy before it could reach the sensitive power source.

Unlike conventional rubber dampers, these wire rope isolators were multi-directional—capable of handling shocks from any angle. This was essential for defense vehicles, where terrain shifts could send unpredictable jolts in every direction.

The Science of Isolation

As the vehicles powered through rocky trails, the suspension systems absorbed some impact, but the intense vibrations threatened the internal electronics. Here, the wire rope isolators performed their silent duty. The compressed metal cables flexed and twisted, converting kinetic energy into heat, which harmlessly dissipated.

With their resilience to extreme temperatures and exposure to oil and debris, they remained reliable even in the harshest conditions. This ensured the batteries maintained stable voltage, preventing premature failure and ensuring that mission-critical equipment—from communication systems to targeting computers—remained operational.

A Mission Accomplished

As the convoy reached its destination, the engineers ran diagnostics. The batteries, despite enduring relentless shocks, maintained peak efficiency. Captain Arjun nodded in approval. In warfare, victory often hinges on the smallest details. And today, wire rope isolators had played their part—silently defending the lifeblood of the operation.

APPLICATIONS OF WIRE ROPE ISOLATERS

Wire rope isolators are used in various industries where shock and vibration control is essential. Here are some key applications:

- Military and Defense Equipment: Used in armored vehicles, missile systems, and sensitive electronics to protect against harsh terrain and impact.

- Aerospace Industry: 2.Installed in aircraft components to reduce vibrations affecting navigation and communication systems.

- Medical Equipment: Helps stabilize imaging devices like MRI and CT scanners, ensuring precision and reducing interference.

- Industrial Machinery: Used in heavy-duty equipment to minimize vibrations that could damage motors, pumps, and control panels.

- Seismic Protection: Applied in buildings and infrastructure to absorb shocks from earthquakes and prevent structural damage.

- Marine Applications: Used in ships and submarines to isolate vibrations from engines and mechanical systems.

Wire rope isolators offer unique advantages compared to other isolation methods like rubber mounts, springs, and foam-based dampers. Here’s how they stack up:

- Durability – Wire rope isolators are highly resistant to extreme temperatures, oil, chemicals, and environmental wear, making them ideal for harsh conditions. Rubber mounts, on the other hand, can degrade over time due to exposure to sunlight, ozone, and solvents.

- Multi-Directional Isolation – Unlike rubber mounts that primarily work in compression and shear, wire rope isolators provide isolation in all directions, making them more effective for unpredictable shock and vibration.

- Longevity – Rubber mounts tend to stiffen and lose effectiveness over time, whereas wire rope isolators maintain their performance for extended periods.

- Space Efficiency – Springs generally offer better vibration absorption in compact spaces compared to rubber, but wire rope isolators can be designed for small areas while still providing excellent isolation.

- Shock Absorption – Wire rope isolators convert kinetic energy into heat, dissipating shocks efficiently. Rubber mounts have built-in damping but may not handle extreme impacts as well.

Advanced Wire Rope Isolators for Defense Equipment in Indian Terrain

In the demanding world of defense applications, where equipment must endure extreme conditions, the choice of vibration isolation technology is critical. Indian terrain presents unique challenges—harsh climates, rugged landscapes, and unpredictable shocks—that require robust engineering solutions. Our Indian-manufactured wire rope isolators are designed to outperform overseas alternatives, ensuring superior protection for defense, aeronautical, and marine applications.

Challenges of Indian Terrain

India’s diverse geography—from the scorching deserts of Rajasthan to the icy heights of Ladakh—poses significant threats to military equipment. Defense vehicles and electronic systems must withstand:

- Extreme Temperature Variations – Equipment faces intense heat, humidity, and freezing cold.

- High-Vibration Environments – Rough roads, rocky terrain, and battlefield conditions generate continuous shocks.

- Corrosion Risks – Exposure to moisture, salt, and industrial pollutants accelerates material degradation.

Our Superior Construction

Unlike overseas manufacturers who use aluminum lugs and galvanized mild steel wire, we employ mild steel lugs and SS 304 wire, offering enhanced corrosion resistance. This ensures:- Extended Durability – Our isolators withstand harsh environments without degradation.

- Longer Warranty – We confidently extend a 4-year warranty, surpassing the standard offered by overseas manufacturers.

- Reliable Performance – Our design ensures sturdiness, making it ideal for defense, aeronautical, and marine applications.

Quality Assurance & Traceability

Defense buyers demand absolute reliability. We provide:- Material Certificates – Verifying the authenticity and quality of raw materials.

- Testing & Inspection Reports – Ensuring compliance with stringent defense standards.

- Product Traceability – Each isolator is uniquely identified for tracking and verification.

The ARCOR Process: A Patented Innovation

Our ARCOR process, developed by Technique Surfaces, represents the latest in liquid nitriding technology. This advanced surface treatment enhances the durability and performance of our wire rope isolators by:- Improving Corrosion Resistance – The process creates a 10–25-micron surface layer of epsilon iron nitride, significantly enhancing protection against environmental degradation.

- Enhancing Wear Resistance – The ductile compound layer delivers outstanding resistance to wear, seizure, scuffing, fatigue, and corrosion.

- Optimizing Anti-Friction Properties – The treatment reduces friction, ensuring smoother operation and extended lifespan.

Why Our Wire Rope Isolators Are Essential for Indian Defense

Given the unpredictable nature of military operations, protecting sensitive equipment is non-negotiable. Our wire rope isolators:- Prevent Equipment Failure – Reducing downtime and maintenance costs.

- Enhance Operational Efficiency – Ensuring uninterrupted performance in critical missions.

- Support Indigenous Defense Manufacturing – Strengthening India’s self-reliance in defense technology.