Hydraulic Buffer Return Mechanisms & Reliability: Why Adoni Tech Leads the Industry

Hydraulic buffers are unsung heroes in mechanical systems, absorbing kinetic energy to protect equipment from damaging impacts. Their reliability and return mechanisms are critical to performance across industries—from heavy machinery to specialized applications.

At Adoni Tech, we combine cutting-edge engineering with decades of expertise to deliver hydraulic buffers that set industry benchmarks. Let’s explore how return mechanisms work, factors influencing reliability, and why Adoni Tech stands apart as a trusted manufacturer.

Understanding Hydraulic Buffer Return Mechanisms

The return mechanism is what ensures a hydraulic buffer resets after absorbing energy. Here’s how common systems work, and how Adoni Tech optimizes them:

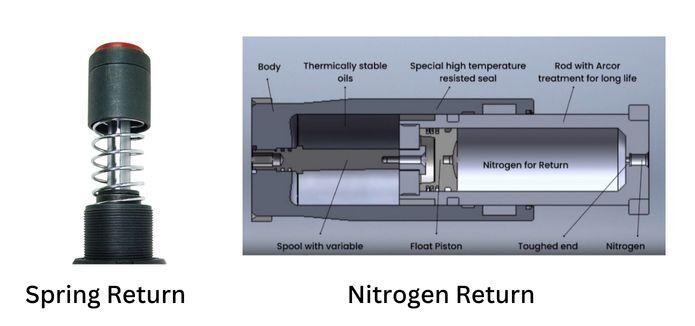

- Spring Return Mechanism

- How It Works: A mechanical spring compresses during impact, storing energy. The spring’s elasticity then pushes the piston back.

- Adoni Tech’s Edge: We use fatigue-resistant, high-grade alloy springs that withstand millions of cycles. Our proprietary heat treatment process enhances durability, ensuring consistent performance even in high-frequency industrial applications like conveyor systems.

- Nitrogen (Gas) Return Mechanism

- How It Works: Compressed nitrogen gas provides a powerful return force. During compression, hydraulic fluid displaces a gas piston, which then expands to reset the buffer.

- Adoni Tech’s Innovation: Our buffers feature precision-calibrated gas chambers with leak-proof seals. By fine-tuning gas pressure, we customize return speeds for heavy-duty cranes or mining equipment, ensuring smooth, reliable operation under extreme loads.

- Viscoelastic Material Return

- How It Works: Specialized materials (e.g., polymer composites) deform under impact, absorbing energy, then gradually return to shape.

- Adoni Tech’s Expertise: We integrate advanced viscoelastic compounds with tailored viscosity profiles, ideal for vibration damping in sensitive machinery. Our R&D team optimizes material blends for controlled, predictable returns in aerospace and automotive testing systems.

Hydraulic Buffer Reliability: Key Factors & Adoni Tech’s Solutions

Reliability hinges on design, materials, and maintenance. Here’s how Adoni Tech ensures longevity across applications:

Industrial Applications: Where Failure Isn’t an Option

In industries like steel plants or port cranes, hydraulic buffers are safety-critical. Adoni Tech’s buffers excel here due to:

- Zero-Leak Seals: Our patented dual-lip seals prevent fluid loss, even under rapid recoil cycles.

- Temperature-Stable Fluids: Hydraulic oils retain viscosity from -30°C to 150°C, ensuring consistent recoil damping.

- Rigorous Testing: Every firearm buffer undergoes 10,000+ impact simulations to guarantee reliability.

Why Choose Adoni Tech? Our Strengths at a Glance

- Decades of Expertise: Over 10 years of innovation in fluid dynamics and shock absorption.

- End-to-End Quality Control: ISO 9001-certified manufacturing with batch testing for every component.

- Sustainability Focus: Eco-friendly hydraulic fluids and 100% recyclable materials. Global Trust: Trusted by Fortune 500 companies and DRDO.

- Global Trust: Trusted by Fortune 500 companies and DRDO.

- Lifetime Supportt: Free Catalogs,3D Models & Drawings, maintenance guides and 24/7 technical assistance.

Conclusion: Reliability Engineered to Perfection

Hydraulic buffers are only as reliable as their design and manufacturer. At Adoni Tech, we blend precision engineering, robust materials, and relentless innovation to create buffers that outperform in the toughest conditions. Whether your application demands industrial-grade durability or specialized recoil control, trust Adoni Tech to deliver unmatched reliability.

Explore our hydraulic buffer solutions today at www.adonitech.co.in – where every impact is an opportunity to prove excellence.